THE SHORT STORY OF WHY INDUCTION CONVERTER INTERFACE DISCS ARE A SCAM AND WHAT YOUR REAL ALTERNATIVES ARE

There are two main instances in which you might even think about using induction converter discs (also known as induction interface discs):

- You already have some non-induction compatible cookware and want to use them on your new induction stove. (If a kitchen magnet strongly sticks to the bottom of your pots and pans, then they are induction-compatible.)

- You have an induction stove, but you heard that copper cookware is the best. And unfortunately, most copper cookware is not induction-compatible. (Exception: Prima Matera, which I reviewed here.)

In both cases, the only way to make non-induction cookware work with induction stoves is to buy an induction converter disc, which is also known as an induction interface disc.1 Such a disc is usually made out of magnetic stainless steel.2 The disc absorbs the magnetic waves from the induction stove and converts that energy into heat.

My advice? Do not use induction converter discs unless you absolutely have to, because you lose a ton of efficiency, and the disc gets so hot that it can damage some induction stoves. If you have a few pieces of induction-incompatible cookware that you want to keep using despite getting an induction stove, then get a portable butane stove, like the Iwatani ZA-3HP Portable Butane Stove Burner. (I reviewed it here. I use that model in my thermal testing and can vouch for its reliability–it’s not a shoddily-built Chinese knockoff. You can use the Iwatani with non-Iwatani butane canisters

, which tend to be cheaper than Iwatani butane canisters

. Iwatani claims other companies’ canisters may have dirtier fuel, but I haven’t noticed much of a difference. Nevertheless, for sake of consistency I always use the same brand for all my thermal tests.)

Alternatively, you could get a portable electric resistance coil stove, though it will heat up and cool down more slowly and cannot do double duty as a camping stove unless you want to run it off a generator. Furthermore, portable coil stoves are far less powerful than good butane stoves.

THE LONG STORY OF WHY INDUCTION CONVERTER INTERFACE DISCS ARE A SCAM AND WHAT YOUR REAL ALTERNATIVES ARE

Induction cooking stoves are only compatible with strongly ferromagnetic materials, such as magnetic stainless steel.3 Magnetic stainless steel is not exotic stainless steel; it’s just a cheaper grade of stainless steel that replaces expensive nickel with cheap iron. Magnetic steel is strongly magnetic, but is also less corrosion resistant than 18/8 or 18/10 stainless steel.

Many cookware manufacturers bond a thin plate of magnetic stainless steel to the bottom of their disc-base cookware. If a pan or pot is of a cladded design (equal thickness on the bottom as on the sidewalls), the entire exterior surface may be made out of magnetic stainless. Either way, these types of cookware do not need induction converter discs, and there aren’t air pockets between the bonded layers of metals.

Some cookware is not natively induction-compatible; they require the use of induction converter discs:

- Aluminum pans that do not have a thin plate of magnetic stainless on the bottom are NOT natively induction compatible. These pans are much more susceptible to warping (bending/flexing) and are often coated with nonstick material such as Teflon or some other PTFE.

- Copper pans that do not have a thin plate of magnetic stainless on the bottom are also NOT natively induction compatible.

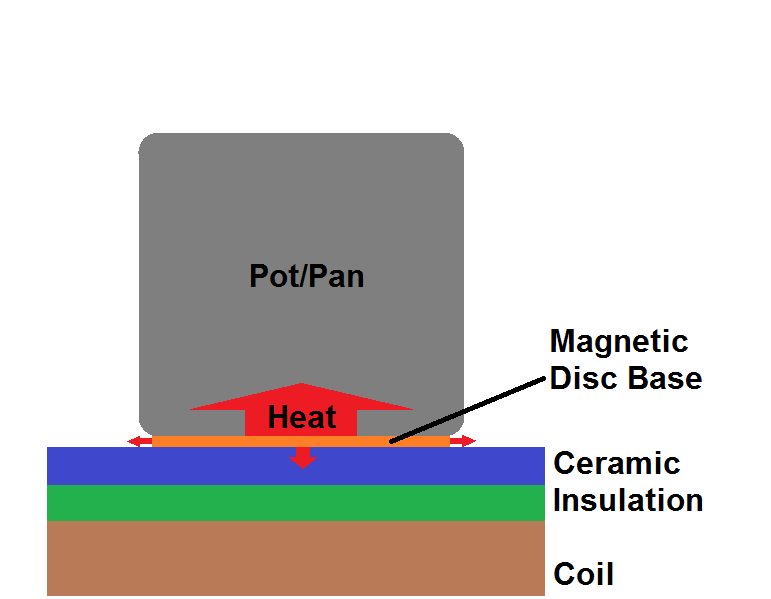

So what happens when you use a induction stove with natively induction-compatible cookware? The induction stove emits magnetic waves, which are captured by the magnetic stainless steel bottom of the pot. That thin sheet of magnetic stainless is the hottest part of the entire system. The heat from the magnetic stainless is mostly conducted upwards, because aluminum is an excellent thermal conductor and quickly transfers that heat into the pot; there are not enough air bubbles to worry about between the bottom magnetic steel surface of the pot and the aluminum above it. Some of the heat is wasted, though: some heat goes down into the induction cooker itself, and a very small amount of heat is radiated or convected (via air currents) to the sides, into your kitchen air.

Ceramic and insulation are terrible heat conductors, so what usually happens for a frying or saute situation is that you finish cooking before the ceramic heats up that much. For example: I usually drape paper towels over my induction cookers to catch any drips and to avoid scratching my cookware or the induction cooker’s ceramic top. The paper towels start to smell bad and brown as they approach 450F, but for shorter cooking sessions, the paper towels usually do not get that hot. Even for long boils, the ceramic can not be higher temperature than the bottom of the cookware, so the ceramic will never be much hotter than 212 degrees Fahrenheit (100 degrees Celsius) for a sea-level boil in a normal stock pot.

Trivia: induction stove magnetic waves penetrate only a tiny fraction of an inch into the magnetic stainless steel, so a thicker layer of magnetic stainless steel is unnecessary.

What happens if you introduce a converter disc between the pot and the induction stove? The magnetic waves are absorbed by the stainless steel in the converter disc, converted into heat, and transferred to the pot. So in theory, using a converter disc isn’t much different than not using one.

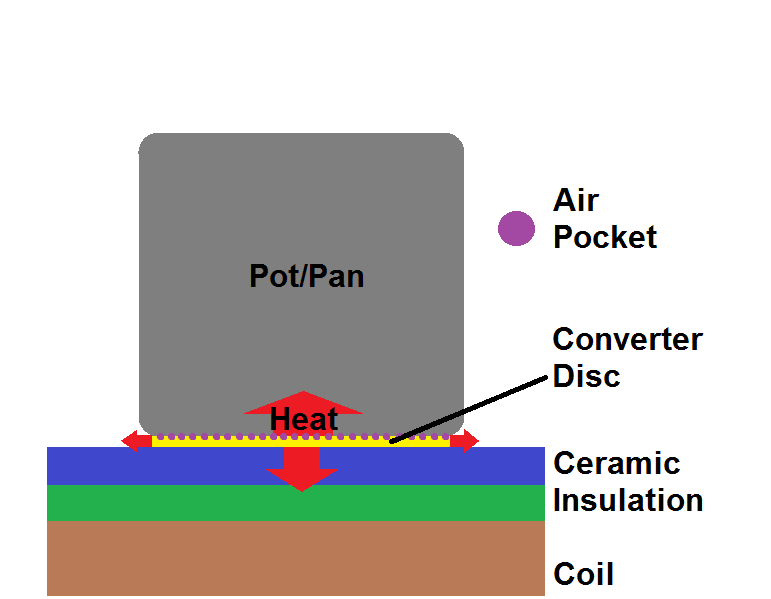

In practice, that’s not what happens. For cookware, metal is never polished perfectly. Under a microscope, even cookware with a so-called “mirror” finish is not flat! You would see jagged peaks and valleys. So when you place a pot on a converter disc, those imperfectly-smooth metal surfaces trap countless microscopic pockets of air between them. Air is an insulator–it does not conduct heat well.

So what really happens when you use a converter disc is that the disc heats up, and it tries to deliver that heat to the bottom of the pot, but those pockets of air drastically slow down the heat transfer. Consequently, the heat builds up in the converter disc, and the disc becomes much hotter than the bottom of the pot. Some of this backed-up heat is conducted downward into the ceramic (which is also a bad insulator but not quite as bad as air); the rest of that backed-up heat goes into your kitchen air. That heat is wasted because it should have gone into the pot instead.

To get a sense of how big the efficiency impact of converter discs are, I boiled water in two identical pots on two identical induction cookers. My testing setup consisted of a pair of Vollrath Mirage Pro 59500P 1800W portable induction cookers, a pair of Sitram Profiserie 4-Quart Half Stockpots (I review the Sitram Profiserie series here), a pair of P3 P4400 Kill A Watt Electricity Usage Monitors

, a Polder 898-95 Clock, Timer and Stopwatch, Black

, a VonShef Induction Hob Heat Diffuser Stainless Steel with Heat Proof Handle, Small (7.5 Inch Diameter)

, and a Fieldpiece ST4 Dual Temperature Meter

.

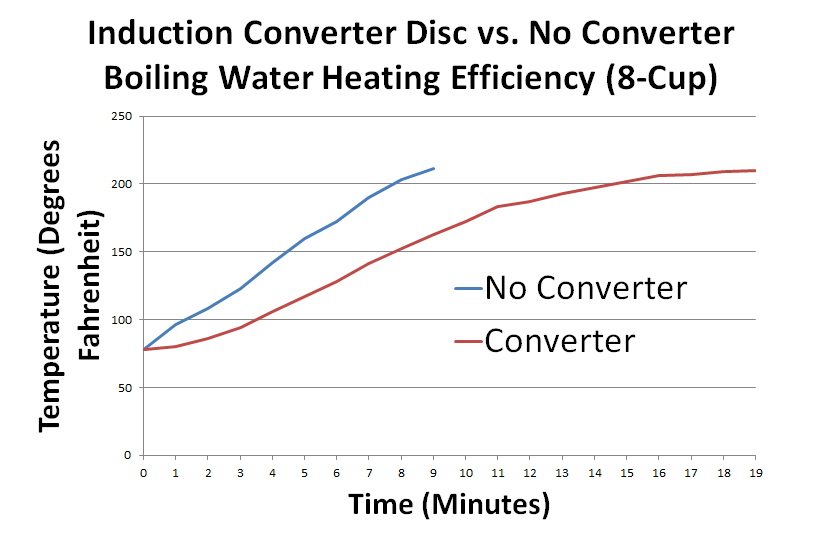

I filled the pots and covered them with lids and let them rest for over 24 hours to ensure that they would be at the same temperature. Each pot received 1.875 kg of water (about 7.93 cups, or 1.98 quarts). I did this test after a hot day so the ambient air temperature was 84F but the water had not heated that high yet and was at 78F for both pots. I placed identical paper towels on each induction cooker and set both of them to draw about 1500 watts.

- After about six minutes, I smelled the odor of browning paper towels emanating from the induction cooker with the converter disc.

- After about 8 minute and 40 seconds (0.22 kWh), the no-converter pot achieved a strong rolling boil. There was no browning of the paper towel underneath the no-converter pot. Meanwhile, the converter pot barely reached 160F.

- After about 10 minutes and 30 seconds, the converter pot’s induction stove started throttling down from an average of ~1500 watts down to ~1200 watts, presumably because the converter disc was so hot for so long that it was starting to overheat the induction cooker’s electronics underneath the ceramic and insulation. I decided to keep going despite the throttling, to simulate what a home chef might experience.

- At about 19 minutes, the converter pot limped to 210F with spikes up to 211F. It wasn’t a rolling boil, but I decided to stop the test anyway because I didn’t want to damage the induction cooker. A brown circle of paper towel lay directly underneath the converter disc. There were three small patches of water or oil stains in the paper towel. I washed my hands prior to the test so it’s possible that I left a little moisture on the paper towels, but I don’t think it materially impacted the test. If anything, more browning occurred on the side of the circle with the three small patches. The darkest browning occurred towards the handle of the converter disc. Total energy consumption: 0.41 kWh. So it took twice as much energy to boil water with a converter disc than with a pot that did not need a converter disc.

One might argue that the converter pot was placed at a disadvantage, because the converter disc had to heat up the extraneous magnetic stainless steel layer on the pot bottom. If you put an all-aluminum pot on the converter disc, it wouldn’t have that magnetic stainless layer. Although that’s true, this is offset by the following:

- The disc and pot were relatively scratch-free and clean. In practice, many pots have more scratches and thus more air pockets of insulation. And if you tried to use something bumpy like hand-hammered copper, you would trap huge air pockets that would hurt efficiency even more.

- Boiling temperatures are relatively tame. If I had tried to fry meat in a pan instead, the induction cooker with the converter disc would have taken even longer to reach proper cooking temperature, if it didn’t shut itself down first for safety. As it was, even a simple boiling of 2 quarts of water caused the induction cooker to overheat and throttle.

- 8 cups of water holds a lot of heat; if we compared a smaller amount like 2 cups to simulate frying eggs, you would see an even greater speed and efficiency difference between the converter pot vs. non-converter pot.

Now, none of this is to say that induction converter discs can’t work at all. I performed another test, this time with a Mauviel M’Heritage Copper M250C 6504.26 10.5 Inch Round Frying Pan. To simulate quick cooking scenarios, I fried three eggs:

The entire process took fewer than five minutes and produced only a modest amount of browning on the paper towel, much to my surprise. (I could still smell some browning, though.) Apparently copper–which is the best heat conductor out of all metals other than silver–does a good-enough job of pulling heat away from the induction converter disc so that the paper did not brown that much. Nevertheless, I would avoid doing any high-heat frying, or frying for extended periods of time. Quick frying, or lower-temperature sautes that don’t take too long, or boiling water should work decently, albeit not that efficiently. The Mauviel was brand new with a very smooth bottom. A scratched-up copper pan would have more scratches and thus lower thermal transfer and thus more browning of the paper towel.

I also tried boiling with copper: 2.5 cups of water boiled in 5 minutes at about 1700 watts. Many induction cooktops can go over 3000 watts on their Power Boil settings. Results:

That wasn’t so bad, but once again: I used a smooth, flat pan on 1700 watts, which is only half the strength of many induction cooktops/ranges. So yes, you can boil on copper on an induction converter disc without burning up your induction unit, but it’s still not a great result considering that a native-compatible induction stockpot would not brown the paper towel at all.

After all equipment cooled down, I tried using an All-Clad MC2 frying pan, which is built out of about 3 mm of aluminum with ~0.5 mm of stainless steel on top. It’s a great performer on electric coil and gas stoves, and I hoped that it would do well with the induction interface disc for frying eggs at least.

Not only did the pan take a lot longer to preheat than on electric coil or gas, but the induction converter disc quickly browned the paper, which smelled terrible. Aluminum alloy has much lower thermal conductivity than copper (albeit much better than cast iron or carbon steel), so aluminum apparently does not pull frying-temperature heat away from the converter disc fast enough to prevent heat congestion and thus overheating. Like the copper pan, the aluminum pan was basically new with no real scratches on the bottom. A well-used aluminum pan would have more scratches and thus lower thermal transfer, and thus even more browning. So I would not recommend using aluminum-bottomed cookware with induction interface discs, not even for boiling water.

Natively induction-compatible stockpots with aluminum discs built-in are plentiful and relatively inexpensive, and you get more efficient boiling with them. And once again, no browning of the paper towel means the converter disc didn’t overheat, and that means your induction cooker’s electronics didn’t get stressed as much, resulting in longer service life of the induction cooker. (Electronic circuits hate heat. The hotter the circuits in your induction stove get, the shorter their lifespan.)

By the way, I did try boiling water with a hammered copper pan but had to shut down that test quickly because the air pockets with hammered-bottom cookware are even bigger than with flat-bottomed cookware, resulting in overheating/browned paper towels. So don’t try to use hammered cookware with induction converter discs.

CONCLUSION

Avoid induction converter discs if possible. They don’t work with aluminum that well, though they sort-of work with copper–provided that they are flat-bottomed and you stay away from higher temperatures like with searing, or lengthy frying sessions.

Regardless of whether you use aluminum or copper, in all cases you lose a lot of pan responsiveness and can overheat your induction cooker, because electronic circuits degrade much faster at higher temperatures. With natively-compatible induction cookware, only the hottest and/or longest sears produce much browning of the paper towel. Scrambling eggs for five minutes produces no paper-towel browning at all. Therefore natively-compatible cookware doesn’t heat your induction cooker as much as using non-native cookware with induction converter discs.

This problem is not limited to VonShef’s induction converter discs. You get the same problems with the Max Burton 6010 8-Inch Induction Interface Disk, Mauviel M’plus 7500.00 Interface Disc for Induction Cooking

, etc. The problem is not the disc: it’s the air pockets.

ALTERNATIVES TO USING AN INDUCTION CONVERTER DISC

If you have a few pieces of induction-incompatible cookware that you want to keep using despite getting an induction stove, then get a portable butane stove, like the Iwatani ZA-3HP Portable Butane Stove Burner. (I reviewed it here. I use that model in my thermal testing and can vouch for its reliability. You can use the Iwatani with non-Iwatani butane canisters

, which tend to be cheaper than Iwatani butane canisters

.) Alternatively, you could get a portable electric resistance coil stove

, though it will heat up and cool down more slowly and cannot do double duty as a camping stove unless you want to run it off a generator.4

The best, long-term solution is to use cookware that is natively induction-compatible:

- Most stainless steel cookware built since the 1990s is induction-compatible. Magnetic stainless is cheaper to make than 18/8 or 18/10 stainless, and the manufacturer gets to claim induction-compatibility as a marketing bonus.

- For aluminum, there are induction-compatible PTFE and ceramic options out there which are natively induction-compatible and don’t cost that much: Anolon Nouvelle Copper, Ozeri Green Earth, and T-Fal Professional Total Nonstick (click on any of those names to see the review page).

- For copper, there is only one product line of thick copper cookware with magnetic stainless steel bottoms: Prima Matera (I reviewed it here). If you don’t mind thinner copper that heats less evenly, but still performs decently, then see All-Clad Copper Core (I reviewed it here).

FOOTNOTES