Rivets and welds are by far the most popular choices for fastening handles onto lids and cookware. Screw and body-extension handles are other common ways of affixing handles to cookware. I would recommend welded handles whenever it’s within your budget. I wouldn’t reject a pan solely on the basis of having rivets, though, especially if there are no alternatives that fit your budget.

TYPES OF WAYS TO ATTACH HANDLES TO COOKWARE

-

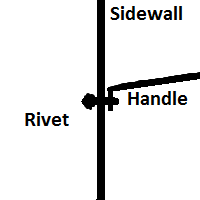

Riveted handle Rivets are small pieces of metal that are crushed into position between two harder pieces of metal. The resulting rivet holds the two pieces of metal together. Rivets can be made out of almost anything, but are usually made out of aluminum or steel.

- Welds are created when you melt two pieces of metal together, sometimes with a filler material.

- Brazing is when you take two pieces of metal with high melting point and join them by heating a small amount of metal between them which has a lower melting point. Brazes have problems when temperatures reach the softening or melting points of the brazing material, and they are not commonly used for modern cookware handles.

- Screwed-on handles use a screw to fasten the handle to the actual cooking vessel. You typically only see this design on cheaper cookware or on high-end European cookware (which often use multiple stainless steel screws per handle). Some people think screws look tacky. Screws are cheap but effective, and you can tighten the screw yourself. If the screw rusts due to being made from a inferior grade of stainless steel, you can replace the screw yourself. However, this is usually a hassle since you have to find or make a screw of the correct length. Nevertheless, at least it is a user-replaceable part, unlike welds and rivets and brazes.

- It’s possible to form the handle of cookware as an extension of the body of the cookware itself, such as with cast iron pans. While the resulting handles may be strong, the drawback is that the pan handle gets hot when used, as a result of being made out of the same, heat-conductive material as the body.

ADVANTAGES OF WELDED HANDLES VS. RIVETED HANDLES

If you are okay with rivets being potentially harder to clean, then don’t stress about rivets vs. welds; either will be fine.

If you care about ease of cleaning, then welded handles do have some advantages. Welded handles are:

1. More hygienic. Food and bacteria do not have any cracks to collect in.

2. Easier to wash. Rivets are more of an issue with frying pans and saute pans because they deal with higher temperatures that can burn grime onto or near rivet heads. In contrast, stock pots usually deal with only boiling temperatures, so there is less chance of grime burning onto rivets. If you do manage to get grime onto a rivet, it can be hard to get the grime completely off. An ordinary kitchen sponge might not be able to clean close enough to where the rivet meets the sidewall of a pan. You can reach that area with a toothbrush and some Barkeepers Friend, if necessary.

This is less of an issue for those who use dishwashers. But be careful to stay away from harsh dishwasher detergents. Use mild ones like Seventh Generation if you must use the dishwasher at all. Also keep in mind that detergents will wear away highly reactive metals like non-anodized aluminum and copper. (Stainless can tolerate dishwasher detergents much better.) So don’t put cookware with bare aluminum or copper into the dishwasher. If it’s just a decorative band and everything else is stainless, like All-Clad Copper Core, you might be able to get away with it, but it will make the copper look dirty.

3. Non-disruptive to nonstick coatings. It’s possible to have internally flush rivets such as Anolon Nouvelle Copper, but most nonstick cookware using rivets have bumpy rivets that interrupt the smoothness of the pan. Cheap pans don’t coat those rivets with nonstick, so you wind up with a pan that is mostly nonstick but with two sticky spots: the rivets. And if you then try to scour the rivets during cleaning with a regular sponge, you may eventually damage the nonstick coating near the rivets as well. Use non-scratch sponges for nonstick pans.

DISADVANTAGES OF WELDED HANDLES VS. RIVETED HANDLES

Welded handles do have some disadvantages:

1. Handle failure is potentially sudden and severe. Rivets work themselves loose over time, so you will have warning before rivets break. On the other hand, welds can seems fine all the way up to the point where they break–potentially with a bunch of hot soup spilling out onto someone’s lap. To lessen your chances of having this problem, avoid welded cookware where the manufacturer does not claim any particular grade of stainless. If they aren’t bragging about 18/8 or 304 or better, it’s probably because they are using worse grades of stainless that are less expensive, but also less corrosion-resistant. And if they are cheapening the product that way, they may also be using cheap welds.

Also, the larger the number of welds, the better, as the welds mutually reinforced each other and provide redundancies in case one or more of the welds fail. Some heavy-duty stock pots have six or more welds per handle.

2. It’s hard to weld handles on aluminum and copper cookware. Aluminum and copper cooking vessels are almost always riveted instead of welded, because they have lower softening and melting points than stainless steel. It’s possible to use screws to attach handles, though.

WELDED HANDLE DURABILITY

Judging by the paucity of welded handles in USA-made cookware, Americans seem to believe that rivets are more durable than welds, but that is a) not necessarily true, and b) it doesn’t necessarily matter. Depending on weld quality and rivet quality, either can be stronger than the other, but the real question is whether they are strong enough for kitchen cookware. We are discussing cookware, not planes or battleships! It doesn’t matter if rivets can be made stronger than welds if even a weld job is more than enough to get the job done–and welds can definitely get the job done. A lot of professional restaurant cookware vessels have no rivets, and they see far harsher conditions than cookware in residential kitchens. Furthermore, Demeyere has issued a video where their 180-pound researcher literally jumps up and down on their welded handles to demonstrate how strong their welds are:

If you want further evidence that welds are fine for cookware handles, even cookware manufacturers don’t claim that welded handles are worse than riveted handles, though they do point out problems with exposed rivets (my emphasis in bold underline):

Present day commercial cookware, such as pots and pans, is generally of all metal construction wherein the receptacle portion of the cooking vessel is‘ made of aluminum and a one-piece steel handle is connected thereto. The handle is connected to the receptacle portion by a plurality of rivets, which extend through openings in the side wall of the receptacle portion and then through openings in the mounting end of the handle. The rivets have rounded heads protruding beyond the inner surface of the receptacle side wall, and the free ends are peened or otherwise expanded ‘beyond the perimeters of the openings in the handle mounting end to rigidly connect the handle to the receptacle.

Although the handle fastening technique described above provides for a very rigid interconnection be tween the handle and receptacle, the protruding rivet heads within the receptacle interrupt the smooth surface thereof so that food tends to collect on and around them. Such collected food is sometimes difficult to remove thereby presenting a sanitation problem if particular care is not taken when the pan is cleaned.

The interior surfaces of many cooking vessels are provided with a nonstick coating, such as TEFLON. In the conventional technique for applying this nonstick material, the receptacle portion of the vessel is spun while the coating is applied. Due to the difficulties of spinning a pot or pan with the handle already attached, the inner surface of the cooking vessel is coated prior to the attachment of the handle. Thus, the heads of the rivets are not coated with the nonstick material, and food that adheres to it is very difficult to remove. In order to remove this food, it is usually necessary to scrub it with an abrasive material, such as steel wool. The nonstick coating, however, cannot withstand such scouring and it quickly becomes rubbed off in the vicinity of the rivet heads. Then, food tends to stick, not only to the rivet heads, but also to the interior surface of the vessel itself in the vicinity of the rivet heads. Obviously, this reduces the effectiveness and life of the cooking vessel.

–Lincoln (Vollrath) Patent US4413767

As the handle must support the weight of the cookware vessel and the contents, which can be considerable if it is full of liquid, the bond between the handle and the cooking vessel must be strong and durable. While it is possible to weld a handle onto the outside of the cookware vessel, attachment with multiple rivets is the preferred assembly method as this process can be highly automated and produces a uniformly consistent and aesthetic appearance in each product produced. [Editor’s note: Note how Meyer did not deride welds as not being durable enough for cookware. Instead, it seems that they would like to use rivets because it’s easier to manufacturer.] While rivets can be avoided in some instances by spot welding a handle to the side wall of a cooking vessel, it is desirable to use a multiple component handle to cover the spot Weld location on the outside of the pan. Thus, frequently for light weight thin aluminum cookware a separate handle is attached by one or more screws to a flange that is spot welded to the outside of the cooking vessel wall. The handle will frequently have a canopy that extends over the sport welded range, thus covering up the welding marks. Such screwed on handles have a less durable appearance, with the potential for the screws to loosen with abuse and poor attention to maintenance.

Although rivet connected handles are ideally suited for heavier duty cookware, in part because they convey the impression of durability [Editor’s note: Not actual durability?] to the consumer, they do have a number of drawbacks. The major drawback to rivets is that the rivet heads protrude into the interior of the cooking vessel. Though many consumers have grown accustomed to this appearance, the inward extending portion of the rivet can be more difiicult clean as for example when the inside of the cookware has a fluorpolymer non-stick coating and the rivets do not. In addition, debris can accumulate and char at the margin between the rivet and the interior cooking vessel surface, requiring extra care and more frequent attention by the consumer or professional cook in cleaning.

–Meyer Corporation, US Patent Application US 2011/0217146 A1

An example of how rivets have little to do with durability and more to do with marketing is the Calphalon Tri-Ply Stainless Steel 1-Quart Open Sauce Pan, which is barely large enough to hold a large orange. A handle attached via welds or two small rivets would be fine, yet this 1-quart sauce pan has three big rivets. It’s overkill that has little to do with durability and much more to do with marketing.

Weld quality does vary, so as a rule of thumb, I would avoid the cheapest welded cookware. You can tell it’s cheap if it does not state a specific grade of stainless steel such as SAE 304 stainless (aka 18/8), because that means it’s probably a lower grade of stainless steel. And if they skimped on the nickel in their stainless steel, they may have skimped on the handle weld quality as well. Try to buy only welded-handle stainless steel cookware if the stainless is advertised to be 18/8 or 18/10 (or 304 or 316).

RIVETED HANDLE DURABILITY

Any decent stainless cookware is going to have decent rivets. They are well-understood and easy to make. So don’t stress out about rivets failing in a residential kitchen situation. You aren’t going to see that happen unless someone really messed up the riveting at the factory.

That said, rivets are not indestructible, so there is only so much abuse they can take before loosening. Rivets made out of weaker materials like aluminum will not suffer wear and tear as well as stronger rivets made out of stainless steel. Every time you hang a pot or fill it with heavy water and move it by the handles, it causes some stress. Every time there is a bit of food or water that manages to find its way into the crack between a rivet and the cookware, it encourages further erosion of that crack. Over time, either the hole widens (if the rivet is harder than the sidewall) or the rivet material is eroded and becomes a smaller diameter than the hole (if the rivet is as hard or less hard than the sidewall). Either way, you get a loose rivet that might collect grime and leak. But as previously stated, you should not worry about breaking rivets in a residential kitchen, because you would not be continually using and abusing the cookware as you might see in a high-volume commercial kitchen.

Finally, if I had to pick bigger holes or eroded rivets, I’d rather have the eroded rivet problem, because at least you still have small holes and can pay to hire someone to re-rivet cookware. If the rivet is harder than the cookware and wears a hole in the vessel, that means bigger holes and the necessity for larger rivets. Re-riveting is costly either way, though, so you would only do it for particularly expensive pieces that you can’t live without, such as antique copper.