COOKWARE EVEN HEATING TESTING METHODOLOGY

I went through several iterations of testing methodologies before settling on two that I thought were realistic and representative of how people use their cookware. I’m also planning on a couple of upgrades and additions to these tests that I thought up on my own, but if you have suggestions on cookware to test or how to make testing methodology even better, let me know.

OLD Electric (Induction, Coil, Radiant, Halogen) Testing

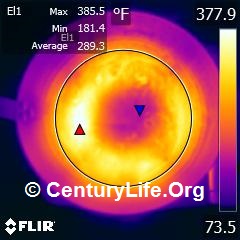

1)” width=”280″ height=”280″ /> Diagram of Pan Bottom (Point B = 350 degrees F 2)

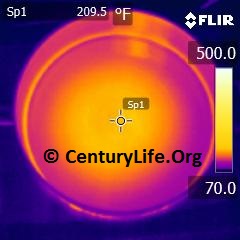

1)” width=”280″ height=”280″ /> Diagram of Pan Bottom (Point B = 350 degrees F 2)

Bottom Line: the lower the temperature delta (difference), the better, and ideally cookware would have a 10 cm temperature delta of zero. That is, ideally the entire cookware surface should be the same temperature.