COOKWARE EVEN HEATING TESTING METHODOLOGY

I went through several iterations of testing methodologies before settling on two that I thought were realistic and representative of how people use their cookware. I’m also planning on a couple of upgrades and additions to these tests that I thought up on my own, but if you have suggestions on cookware to test or how to make testing methodology even better, let me know.

OLD Electric (Induction, Coil, Radiant, Halogen) Testing

1)” width=”280″ height=”280″ /> Diagram of Pan Bottom (Point B = 350 degrees F 2)

1)” width=”280″ height=”280″ /> Diagram of Pan Bottom (Point B = 350 degrees F 2)

Bottom Line: the lower the temperature delta (difference), the better, and ideally cookware would have a 10 cm temperature delta of zero. That is, ideally the entire cookware surface should be the same temperature.

All measurements were with pan and ceramic top both at ~68F (typical room temperature, set by thermostat). I usually allow 6+ hours in-between tests to ensure that pan and ceramic top have both cooled down to 68F.

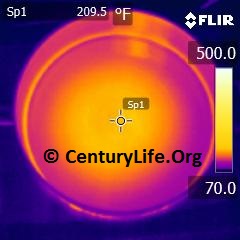

By the way, regarding thermal images: just like visible light can reflect off metal surfaces, so can infrared, so you will see such reflections in thermal images that imply the temperature of something is hotter than it really is; you see this phenomenon in the bottom corners of cookware for example. I could have chosen a more extreme test regime such as comparing the very edge of each pan to the center, but I wanted something standard that could be measured easily even on 10-inch diameter saute pans. Furthermore, the center of the pan is most important, given that most of the food goes there rather than at the edges.

These rankings should hold true for induction as well as electric, such as electric coil heating elements. This is because the heat is produced in the base and there is no hot gas rolling up the sides to help. Some cookware is so uneven-heating that the center would not reach 350F faster than the rest of the pan; in such cases (e.g., cast iron), I refer you to their gas rankings.

NEW Electric (Induction, Coil, Radiant, Halogen) Testing

I upgraded my equipment to the Vollrath Mirage Pro 59500P portable induction cooker, which has 100 power levels and allowed me to nail the wattage down to 800 watts for each piece of cookware, plus or minus ~8 watts (~1%). The Vollrath behaves differently than the Cooktek in various ways. For instance, the Vollrath has a slightly smaller induction coil compared to the Cooktek, and that, plus the additional wattage (10W), means that cookware tends to get worse delta scores when testing on the Vollrath than on the Cooktek. Otherwise the testing methodology is the same as with the Cooktek.

Gas (Butane, Propane, Natural Gas, etc.) Testing

Attempts to use actual natural gas cooktops were unsuccessful due to reflections and repeatability problems. I solved my problems by purchasing several 12,000 Btu/h Iwatani ZA3HP portable butane stoves (I reviewed the ZA-3HP here) and several dozen butane fuel canisters so that I would always have full or nearly-full canisters on hand. Unlike cheaper portable butane stoves, Iwatani stoves utilize patented aluminum heat exchangers: in each Iwatani stove, there is an aluminum block that absorbs heat from the flame and moves it to the fuel canister to prevent the fuel canister from dropping in temperature too quickly. Iwatani claims that this results in a flat heat output until a fuel canister is practically empty. Even so, I only use full or nearly-full canisters just in case. I also have to stop using Iwatani burners after a while because particular buildup lowers their output. So I have a bunch of barely-used Iwatani burners and a lot of nearly-full butane canisters, since I want to stay as close to 12,000 Btu/h as possible for consistency.

I decided to kill two birds with one stone with my gas testing. One, I needed gas testing for non-induction-compatible cookware. Two, I needed high-heat testing. 12,000 Btu/h is roughly double the 5,900 Btu/h equivalent induction tests (above). Thus my gas tests are great for stress-testing cookware to see how they do when you are rapidly heating cookware on what would be “medium high” or perhaps even “high” for most residential natural gas burners.

12,000 Btu/h is more than most cookware can handle. Unlike induction, the initial hot “O” shape never closed for most cookware by the time maximum safe temperatures were reached. I could no longer use the same 10-cm radius delta that I used for induction testing, where I took the temperature at point B and subtracted from that the averaged temperatures of points A and C. Instead, I took a centered 20-cm diameter circle and found the hottest and coldest points in the circle, once any point in that circle reached ~350F. That is, when the hottest point in the circle reached ~350F, I subtracted the coldest point from it. This is the gas 10 cm temperature delta.

FOOTNOTES

[1] I have tested these cookware pieces at a what most people would consider medium to medium-low heat. Each piece in these tests received about 790 watts of power, which assuming 100% conversion (realistically more like 84% conversion) is roughly equivalent to a 5,917 Btu/h gas burner (0.790 x 7,490 = 5,917; this number factors in how gas burners deliver roughly 41% of its energy into the pan, wasting the rest as hot gases that heat your kitchen air instead of the cookware). Why 790 watts? You might expect that an 1800-watt induction cooker at half-power would draw 900 watts at the wall (as measured by a Kill-a-Watt energy-measurement device), but that is not true. Wattage varies. Cookware pieces below ~20 cm base diameter draw less current on the Cooktek. At 20 cm and above, the effect goes away, as the base diameter is large enough to capture virtually all of the energy throw off by the Cooktek’s induction coil. Furthermore, when I use a paper towel draped across the Cooktek unit, the maximum wattage for the unit is more like 1650 watts for the power outlet that I use, and the same setting draws different wattage depending on what circuit I’m on in the house. The Cooktek is also using about 7 watts for non-heating purposes, such as powering the cooling fan and LED readout. Is this a headache? Yes. I have to make sure all cookware gets about the same dose of energy to make it fair. For the above tests, I have adjusted the Cooktek so that all cookware receives about 790 watts in a very tight cluster (plus or minus 10 watts, which is plus or minus 1.2 percent). Most cookware that is induction compatible is just as efficient as cast iron; it’s very rare to find something more efficient, and somewhat rare to find something less efficient. I suspect that it’s because most magnetic stainless steel bottom layers are the same stainless steel type (430). I updated my test to uses Vollrath Mirage Pro 59500P induction cookers, but the methodology is basically the same, with an 800W target instead of 790W.